In ships, turbochargers are forced induction systems that use exhaust gas energy to increase engine power and efficiency by compressing intake air, boosting combustion, and potentially generating electricity.

- Function:

Marine turbochargers, also known as exhaust gas turbochargers, utilize the energy from a diesel engine’s exhaust gases to drive a turbine, which in turn rotates a compressor.

- Mechanism:

The compressor forces more air into the engine cylinders, leading to a more complete combustion of fuel, resulting in increased power and improved fuel efficiency.

- Benefits:

- Increased Power:Turbochargers allow for a significant increase in engine power without increasing the engine’s size.

- Improved Fuel Efficiency:By maximizing the combustion process through increased air intake, turbochargers can improve fuel efficiency in diesel engines.

- Waste Heat Recovery:Some marine turbochargers incorporate a generator on the rotor shaft, allowing for the recovery of exhaust heat to generate electricity for onboard consumption.

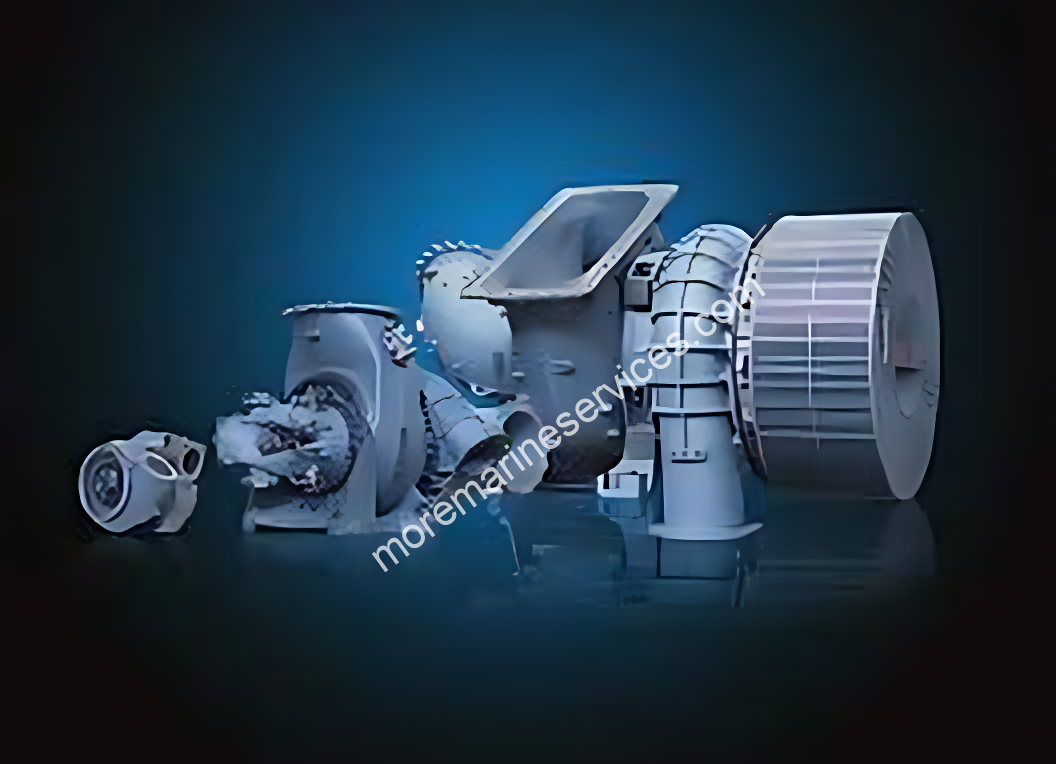

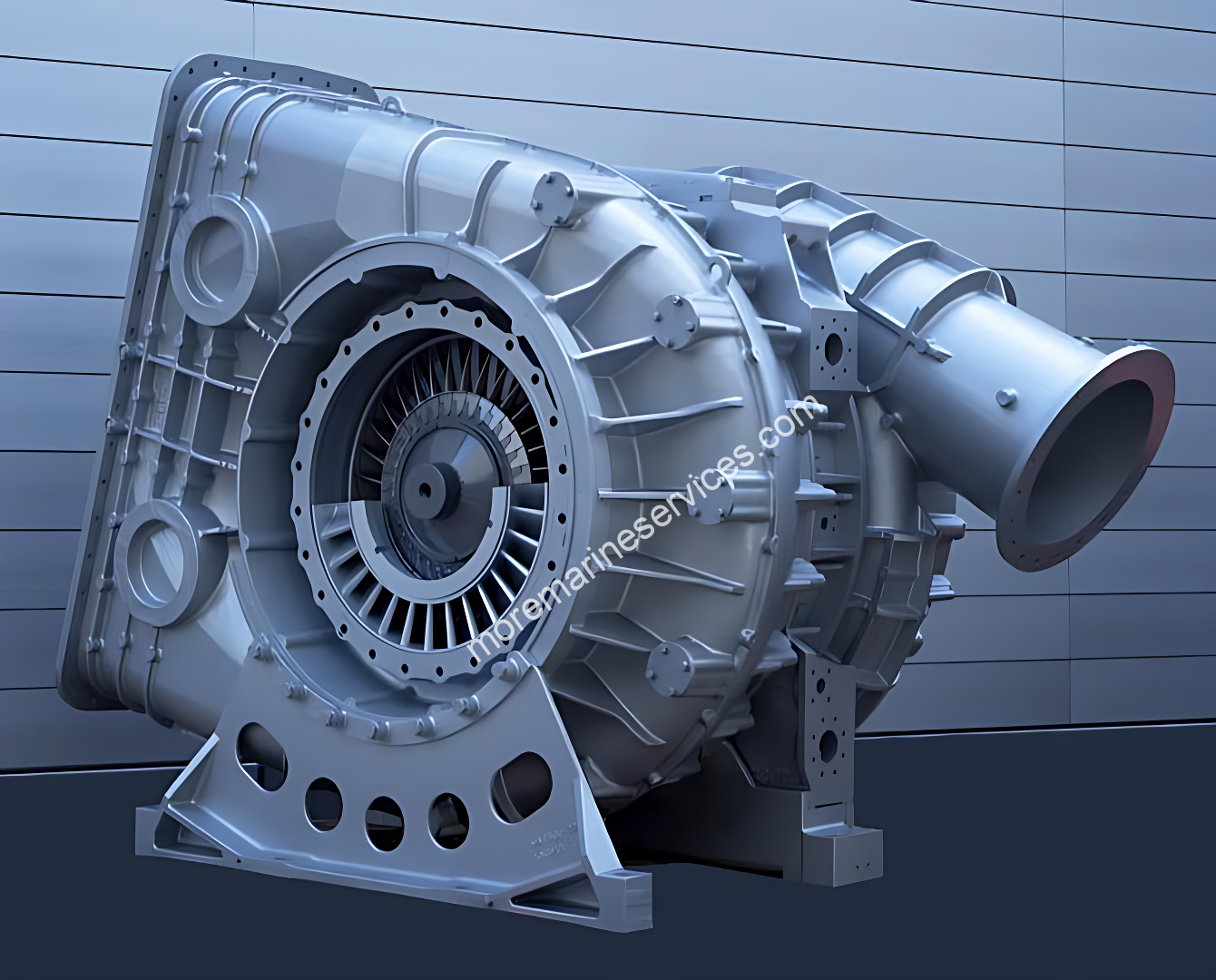

- Construction:

A marine turbocharger typically consists of a turbine connected to a compressor, both mounted on a shaft, and housed within casings.

- The turbine side directs exhaust gases to rotate the turbine blades.

- The compressor side sucks in air, compresses it, and feeds it to the engine.

- Maintenance:

Regular maintenance is crucial to ensure the proper functioning and longevity of marine turbochargers, addressing potential issues like turbine casing corrosion, bearing damage, or blade damage.

- Applications:

Turbochargers are used in various marine applications, including propulsion units, generating sets, and diesel and dual-fuel engines.

- VTI Technology:

Some manufacturers, like MHI-MME, have developed Variable Turbine Inlet (VTI) technology for their MET turbocharger series, which allows for better control of exhaust gas flow and scavenging air pressure, particularly during slow-steaming operations.

Reviews

There are no reviews yet.